Local boiler controls are generally employed for boiler systems functioning in stand alone manner. It is very necessary to set right water levels in the systems such as dry fired boilers owing to the risk involved with their operation.

On the other hand the direct digital controls are mainly applied in situations where multiple boilers are used. DDC controls are individual systems which are capable of handling multi- boiler staging as per demand changes. Moreover, they can control hot water multi-pump functional sequencing as well as home hot water services. Also, they help in collecting and analyzing surplus amount of boiler data. In addition to all, they are provided with an exclusive hot water reset schedule feature which results in smaller cycle rates than exterior temperature of air. These control techniques offer high adaptability and reduced running costs in boiler plant management.

In domestic applications a special device named aquastat is employed for boiler control whereas in commercial boiler applications involving large horsepower boilers far advanced control systems are used. While selecting a boiler control type for a particular application, one must consult experienced control manufacturers and engineers.

Types of Boiler Controls

Based upon the system specifications and user requisites, local boiler controls are directly manufactured inside the factories and made available outside as complete systems. Following are the major controls available for boilers:

- Multi-boiler Staging: In this method, multiple boilers are staged on and off depending upon the load demand. Primarily, a number of cast iron boilers are applied for this selection. Either electro-mechanical control or solid-state control is put into use for this kind of boiler control technique.

- Modulating Control: In this method, the quantity of fuel and air supplied to the burner varies according to the load demand. “It ranges its boiler firing rate from low fire to high fire and everything in between based on specific input temperatures that determine demand such as delta T.”

- In this technique, the steam pressure and hot-water temperature gets measured depending upon which a nonstop control signal is generated. This signal usually serves as an indication for the fuel which needs to be supplied to the burner for combustion. Whenever, there is drop in pressure or temperature, the firing rate increases accordingly. This technique results in better boiler efficiency.

- On – Off Control: In this method, the boiler gets on and reaches up to high fire level and then settles at that stage until a pre-determined set point is attained.

- Step-up/Step-down: In this method of boiler control, more than two firing rates exist depending upon the heating demand. Here, the firing rates generally vary from low to low, high or medium fire.

- Oxygen Trim Control: In this technique, the quantity of oxygen present in the combustion gases is determined and then the available surplus air is cut down to achieve high burning efficiency. This method of boiler control enables sound control of emission as well as excess air. It also results in simple override of carbon monoxide or opacity.

- Excess Air Regulation Control: In this method, a perfect ratio of excess air to fuel supplied is maintained to achieve high burning efficiency as well as reduced heat loss. In general, gas, oil and coal powered boilers do not have the capability to provide a perfect blend of fuel and air. Hence, in these circumstances, the use of this method becomes absolutely essential. Effective implementation of this technique will result in better heat-transfer rates, pre-warning of combustion related issues and considerable fuel savings.

- Air/Fuel Cross Limiting Control: In this technique of boiler control, the air supply is increased prior to an increase in fuel supply as well as the fuel supply is decreased before the air supply happens to drop in the system. Due to this, the safety of the boiler system will always be maintained along with optimized fuel consumption. This cross-limiting combustion-control strategy hence proves to very effective in reducing the danger of explosion due to improper air to fuel ratio in the system. The execution of this method will make the system capable of adapting to quick changes occurring in fuel and air flows. Also, it helps in better fulfillment of steam demand.

- Drum Level Control: This method is often applied for boiler systems in which the drum water level is considered to be significant. If the level of water happens to be very low then it will result in exposure of boiler tubes to the heat and atmosphere which in turn leads to overheating and destruction of these tubes. On the other hand if the level of water happens to be exceedingly high, then it will create problem in separation of moisture from steam ultimately leading to reduced boiler efficiency and transport of undesirable moisture to the process or turbine. Hence, an appropriate level of water must always be maintained in a boiler drum. This level control is always done at constant steam load demand. Three types of drum-level control designs mainly exist for boiler applications which include single-element drum-level control, two-element drum-level control and three-element drum-level control.

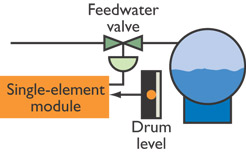

Single-element Drum-level Control

This is a very simple kind of drum level control design. It needs single analog input for its operation and in return provides single analog output. Hence, it is named single element control. “Because there’s no relationship between drum level and steam or feedwater flow, it can be applied only to a single feed pump on a single boiler supplying a relatively stable load.”

Its performance is not as effective as compared to other two level control designs. A typical drum level control with single element module is shown in the figure below.

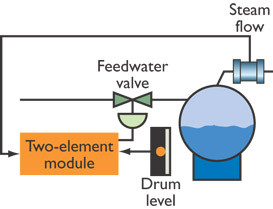

Two- element Drum-level Control

This drum level control design is particularly suitable in case of single drum boilers where the feedwater is available at a constant pressure. “Two-element control includes the same level element used for the single-element configuration but has an added steam-flow element that provides a density-corrected mass flow-rate signal to control the feedwater flow.”

In this design, presence of double control elements tends to provide rigid drum level control. A typical drum level control with two element module is illustrated in the figure below.

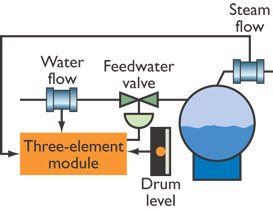

Three-element Drum-level Control

“Three-element drum-level control is suited for handling variable feedwater pressure or multiple boilers with multiple feedwater pumps.”

In this design, three elements are used, each for controlling level, steam and feedwater flow respectively. This system offers far better and advanced drum level control as compared to all other systems. For best control, correct flow values of both steam as well as feedwater must be maintained with regard to density. A typical drum level control with three element module is shown in the figure

below.

References

1. Modulating Control

2. Single-element Drum-level Control

3. Figure1

4. Two-element Drum-level Control

5. Figure2

6. Three-element Drum-level Control

7. Figure3