Discontinued, replaced by the VEEDER-ROOT TO MODBUS AND BACNET QUICKSERVER GATEWAY.

The CAS 2700-02B Veeder-Root Gateway can poll Veeder-Root TLS Panels for status, real-time, and configuration data. The Gateway can be used to read Tank Inventory, System Status, Tank Alarms, Sensor Alarms and more. The Veeder Gateway serves data from a TLS panel as Modbus, BACnet or Web data. The gateway supports all these options simultaneously. Use the data you want and ignore the other.

The Gateway connects to the TLS Panel, reads data and stores it internally. When a remote system requests data, this data is served in a form that is appropriate to the protocol. In the event that the connection to the TLS Panel is lost, or data cannot be read, the gateway can signal this to the remote data client.

The gateway requires minimal configuration and can be considered a plug and play component of a system, in that it is ready to operate out of the box with the default configuration. The Veeder-Root drivers support using an RS232 serial port or TCP/IP Ethernet to connect between the Gateway and the TLS Panel. The Panel, therefore, must have a suitable RS232 card or Ethernet card installed.

Supported Veeder-Root TLS350 Commands

The following is a list of the Veeder-Root TLS350 Protocol Commands that the CAS 2700-02B Gateway supports:

- 101 - System Status Report

- 201 - In-Tank Inventory Report

- 202 - In-Tank Delivery Report

- 301 - Liquid Sensor Status Report

- 406 - Relay Status Report

- B38 - Vacuum Sensor Diagnostic Report

Note: The CAS 2700-02 Veeder-Root Gateway does not support any functions that can configure or change settings on the Veeder-Root panels. As such, all data points that the Gateway makes available via Modbus, BACnet, and Web requests are read-only.

Supported Modbus TCP/RTU Commands

The CAS 2700-02B Veeder-Root Gateway supports the following Modbus TCP/RTU commands:

- 01 (0x01) Read Coils

- 02 (0x02) Read Discrete Inputs

- 03 (0x03) Read Holding Registers

- 04 (0x04) Read Input Registers

- 05 (0x05) Write Single Coil

- 06 (0x06) Write Single Register

- 15 (0x0F) Write Multiple Coils

- 16 (0x10) Write Multiple Registers

Supported BACnet IP Commands

The CAS 2700-02 Veeder-Root Gateway executes, or responds to, the following BACnet IP commands:

- Who-Is

- Who-Has

- ReadProperty

- ReadPropertyMultiple

- WriteProperty

- WriteProperptyMultiple

- SubscribeCOV

- TimeSynchronization

Supported Veeder-Root products

The CAS Veeder-Root Gateway supports the following Veeder-Root Products:

- TLS-450 PLUS Automatic Tank Gauge

- TLS4i / TLS4c Automatic Tank Gauge

- TLS-350 Automatic Tank Gauge

- TLS-350 Plus Automatic Tank Gauge

- TLS-350R Automatic Tank Gauge

- TLS-300C/I Automatic Tank Gauges

- TLS-2/P Automatic Tank Gauge

CAS Hardware 700

The CAS 700 Hardware device contains 2x 9-pin serial ports (1x RS485 and 1xRS232), and one Ethernet port. The device also contains a microSD card where system files, assets, configurations, and logs are stored.

The device has the following system drivers that can be enabled:

- HTTP REST Server - a passive web server with an API that users can interact with the device to get or set values

- HTTP Push Driver - a driver that can be configured to push data in a specific format (JSON, XML, CSV) to a 3rd party web server. Current data formats are Chipkin's default JSON payload and VeederRoot Tank data as JSON. Please contact Chipkin for information on adding additional formats.

Modbus RTU Driver

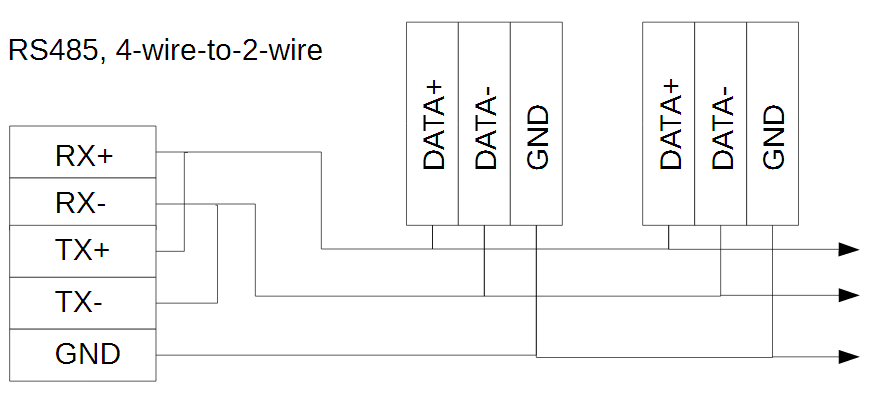

The CAS Modbus RTU driver allows the CAS Gateway to transfer data to and from devices via a serial RS485 connection using the Modbus protocol. The CAS Gateway can either be a Client, reading and controlling values from a slave, or a Server, serving data to a Modbus Master.

The CAS Modbus RTU Driver supports the following Modbus Functions:

| - 01 (0x01) Read Coils | - 05 (0x05) Write Single Coil |

| - 02 (0x02) Read Discrete Inputs | - 06 (0x06) Write Single Register |

| - 03 (0x03) Read Holding Registers | - 15 (0x0F) Write Multiple Coils |

| - 04 (0x04) Read Input Registers | - 16 (0x10) Write Multiple Registers |

Modbus TCP Driver

The CAS Modbus TCP driver allows the CAS Gateway to transfer data to and from devices over Ethernet TCP/IP using the Modbus protocol. The CAS Gateway can either be a Client, reading and controlling values from a slave, or a Server, serving data to a Modbus Master.

The CAS Modbus TCP Driver supports the following Modbus Functions:

| - 01 (0x01) Read Coils | - 05 (0x05) Write Single Coil |

| - 02 (0x02) Read Discrete Inputs | - 06 (0x06) Write Single Register |

| - 03 (0x03) Read Holding Registers | - 15 (0x0F) Write Multiple Coils |

| - 04 (0x04) Read Input Registers | - 16 (0x10) Write Multiple Registers |

BACnet IP Driver

The CAS BACnet IP driver allows the CAS Gateway to transfer data to and from devices over Ethernet UDP/IP using the BACnet IP protocol. The CAS Gateway can either be a Client, reading and storing values from a BACnet device, or a Server, making data available as BACnet objects.

The CAS BACnet IP Driver supports the following BACnet Services:

| - Who-Is | - Who-Has |

| - Read Property | - Read Property Multiple |

| - Write Property | - Write Property Multiple |

| - Subscribe COV | - Time Synchronization |

Note: Chipkin is always updating the BACnet IP Driver. For a recent list of supported services, please visit www.chipkin.com or contact us. If there are services that you require that are not listed, please contact us to discuss how we can add them to the driver.

Veeder-Root Driver

The CAS Veeder-Root driver allows the CAS Gateway to read data from a Veeder-Root Panel using the TLS350 protocol over RS232. The CAS Gateway can connect to Veeder-Root TLS 300/350/450/4 series panels to read and store Tank and Sensor data. This driver only supports read-only functions and cannot command or configure the Veeder-Root panel. The Veeder-Root panel must have a valid RS232 comm card installed.

The CAS Veeder-Root driver supports the following TLS350 functions:

- 101 - System Status Report

- 201 - Tank Inventory Report

- 202 - Tank Delivery Report

- 406 - Relay Status Report

- B38 - Vacuum Sensor Diagnostic Report

Web (HTTP, XML, REST, Json, MQTT) Driver

The Web Diver allows for data to be monitored by remote systems running applications that can issue HTTP or SOAP/XML GET requests – such applications can be easily developed by end users. Of course, this data is available using an Internet Browser such as Internet Explorer or Google Chrome

Specifications

CAS Hardware 700

The following specifications are common to all Chipkin gateways.

- Certifications: UL and ULc approved

- Ports:

- 10/100BASE-T with RJ-45 connector

- 1x RS232 port

- 1x RS485 port (different models have additional ports)

- Power: 7 - 24 VDC through an external power supply. (12V @ 90mA)

- Operating temperature: 0 - 70 °C (32 - 158 °F)

- LEDs: link, speed/data, power

Dimensions

- Dimensions (LxWxH): 107 x 83 x 25 mm (4.2 x 3.25 x 1 in.)

- Connection type: RS485 (jumper change to RS232)

Top

Bottom

Manuals

Resources

A quick start guide with instructions for some of the basic operations of the CAS Gateway product line. Includes instructions for the following:

- Detecting the CAS Gateway via the computer and settings its IP Address

- Downloading the Firmware to the CAS Gateway

- Downloading the Assets to the CAS Gateway

- Downloading the Configuration to the CAS Gateway

The default configuration for a CAS 2700-02B Veeder-Root Gateway.